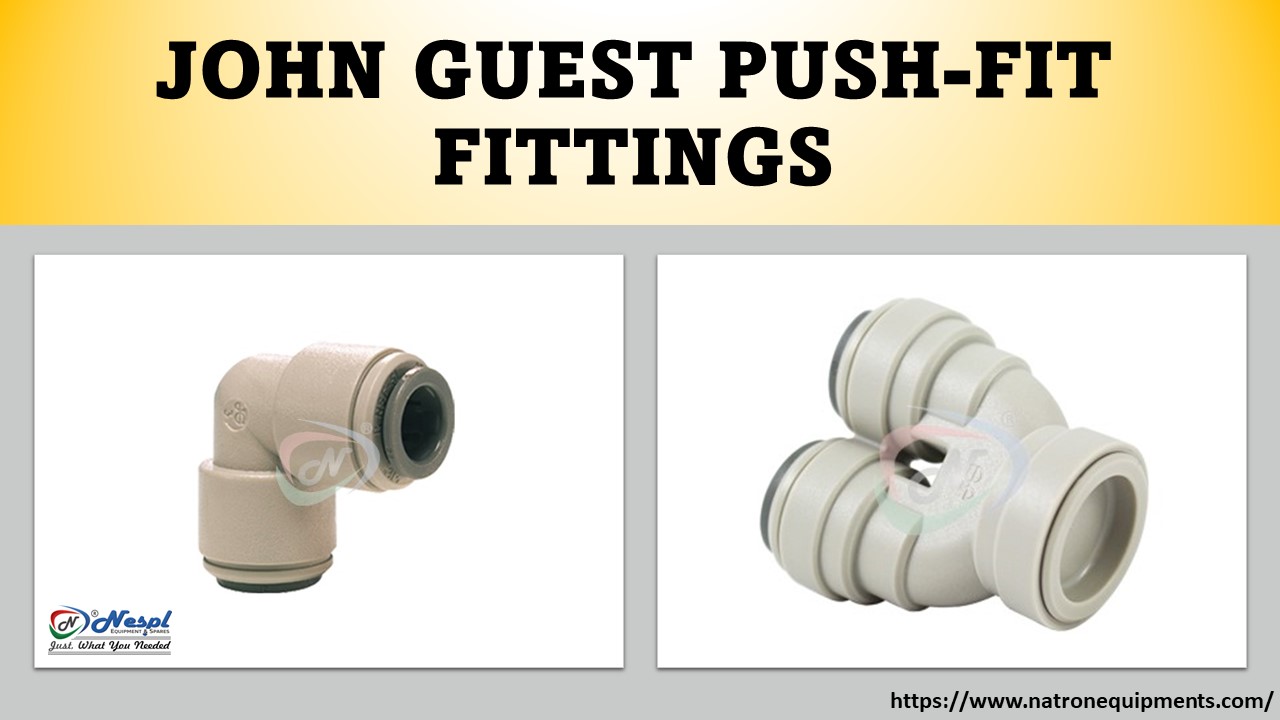

A push-fit product is the result of John Guest’s technology.

With high performance, durability, ease of installation, and a wide range of applications, John Guest’s Push-Fit Fittings are unique and flexible.

Our standard push-fit technology creates a strong and leak-tight seal in the bottom by using stainless steel teeth when mounting and demounting the cartridge.

In addition, they develop advanced solutions to meet the needs of a wide range of industries using our core technology.

They often transfer innovations and ideas from one industry to another, benefitting everyone.

Benefits of Push-Fit fittings:

- Since the fittings are made of plastic, they are not affected by pitting corrosion.

- It is possible to connect copper pipes as well as plastic pipes to these fittings.

- It is possible to connect Push-Fit Fittings while Residual Water remains in the pipework.

- Leakproof and high-performance connections.

- Installation, demounting, and refitting are effortless, requiring no tools.

- There is no need to use hot works, fluxes, or glue during installation.

- In tight spaces, this method is less labor-intensive.

- It is non-toxic, resists corrosion, and does not build up scale.

In addition to plumbing projects inside the home, Push-Fit fittings are perfect for work outside as well. You can find them in water purification systems, Internet connections, boats, caravans, exhibitions, and even in your car to improve its performance.

A unique combination of push-fit and multi-seal technology allows reliable connections to be made in seconds without the use of tools.

John Guest also offers fully demountable fittings which make system modifications and extensions quick and easy. For extra peace of mind, their push-fit fittings are suitable for hot and cold water as well as central heating systems.

How to make the connection?

Prepare Plastic Pipe

- Use John Guest pipe cutter

- Follow the speed fit pipe mark when cutting the pipe

- Push John Guest Insert fully into the pipe

How to Connect fittings to plastic pipe?

- Make sure the pipe is fully inserted into the fitting, up to the pipe stop and pipe mark.

- Pull the connection to check its security.

How to disconnect?

- To disconnect push fittings, the collet square should be pushed against the fitting.

- Place the collet in the desired position and remove the fitting.

Lets make a connection with copper pipe:

- Cut the pipe with a suitable pipe cutter.

- Make sure burrs and sharp edges are removed.

- The pipe should be inserted into the fitting until it reaches the pipe stop.

- Pull the connection to check if it is secure.

As simple as that. Connecting and disconnecting John Guest’s Push-Fit Fittings is simply mind-blowing.

Want to Buy John Guest Push-Fit Fittings

NESPL provides push-fit connection solutions to several industries in India, including beverage, medical, automotive, and others. Our partnership with reliable package delivery companies in India ensures the safe and secure delivery of John Guest products.

We are the place to go if you have a question about john guest products for beverage or industry.

Must Visit: https://www.natronequipments.com/john-guest.html