Many people ask if brass fittings are worth the extra expense, given the variety of choices available today. Among the most common materials used to make pipe fittings is brass. Because of the efficiency of this metal, you can rely on it as a safe, long-lasting component. Brass is the most frequent material used to make fittings, and its unique characteristics make it a suitable option for a range of purposes. Experts frequently use brass pipe fittings because of their dynamic characteristics, including its robustness, flexibility, and corrosion resistance.

There are many uses for brass pipe fittings, such as transporting liquids, chemicals, combustible gasses, and slurries. These pipe fittings come in a variety of shapes and thread sizes, in addition to connecting, adapting, and controlling any liquid or gas in the pipe.

Let’s highlight five benefits of Brass Fittings:

1. Excellent Malleability: Brass has excellent malleable properties, making it easy to shape and twist unlike steel or iron pipes. Compared to other materials, this material is easier to mold, and despite its malleability, brass remains highly durable and reliable.

2. Extreme Durability: Brass is an extremely durable material, thanks to its various working properties. If you are looking for pipe fittings that deliver consistent performance for many years, these pipe fittings are the right choice. Furthermore, these brass fittings will perform optimally in supply lines containing boiling water.

3. Outstanding Flexibility: Various shapes, sizes, and widths are available in brass pipe fittings, making them suitable for use with many kinds of pipes in a plumbing system. Whatever the project – whether it’s a water line into your home or a project with strict specs – these pipe fittings provide high quality.

4.High Resistance to Corrosion: In addition to corrosion and rust, metal fittings can undergo significant wear and tear. Because brass is corrosion-resistant, it is an excellent choice for pipe fittings. These fittings are preferred in areas with high corrosive water properties because of their non-corrosive properties.

5.Exceptional Temperature Tolerance: Brass has a high temperature conductivity and can withstand higher temperatures than other materials. As a result, it is a perfect system for distributing hot water.

These are used in hydraulic, pneumatic, instrumentation, and plumbing systems. In addition to instrumentation gas and chemical transfer, air compressor piping, mobile equipment, packaging equipment, machine tools, and non-potable water plumbing, these equipments are also used for non-potable water.

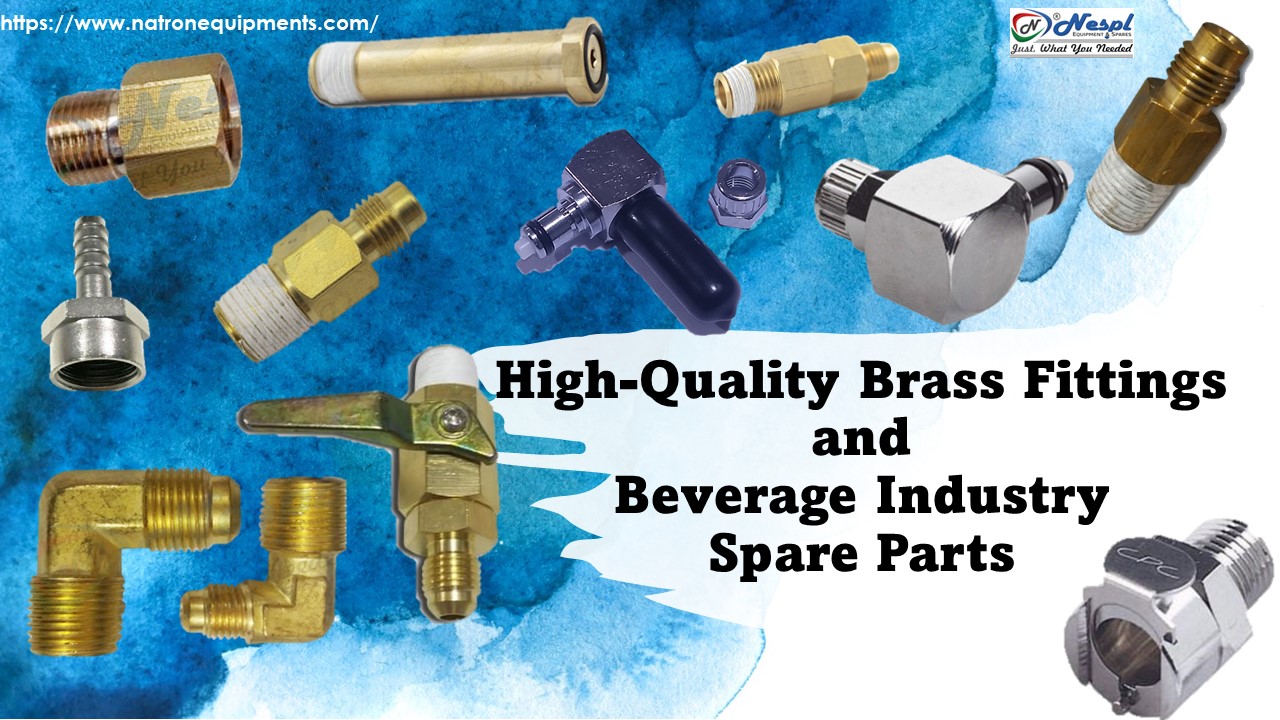

If you’re in need of Brass Fittings, you don’t have to look any further than NESPL. As a premium supplier of Brass Fittings, SS Check Valves, and other SS fittings for the beverage industry, Natron Equipment and Spares Pvt. Ltd. has got you covered. NESPL offers a variety of high-quality products including the Nespl CO2 INLET NRV BRASS, BRASS ELBOW 1⁄4, BRASS ELBOW SET, 3/8 FLARE THREAD X 3/8 NPT PUMP INLET BRASS FITTING, CO2 REGULATOR TO HIGH-PRESSURE CONNECTOR BRASS, BRASS UNION FITTING, BRASS PRESSURE RELIEF VALVE, BRASS 1/4 NPT SOCKET R/H, 25 MM FORGED BRASS COMPACT PRESSURE REDUCING VALVE SCREWED -(1040B 25 MM), MCD21025 – 5/32 PTF VALVED ELBOW CHROME-PLATED BRASS COUPLING INSERT.

To explore more, pls visit: https://www.natronequipments.com/

At NESPL, our extensive product line includes Beer Fittings, Bar Equipment Spare Parts, Soft Drink Industry Fittings and Shurflo/Flojet Pumps Fittings. So, next time you require Brass Fittings or any other beverage industry equipment spare parts, simply connect with us, and we’ll take care of the rest.