Ear hose clamps are easy to install due to their simple, user-friendly design. Below are several reasons why they are popular for both DIY projects and professional applications:

- Simple Design: The straightforward design with two “ears” allows for easy compression and adjustment, making it intuitive to use.

- No Special Tools Required: While pliers can be helpful, ear hose clamps can often be installed by hand, eliminating the need for specialized tools.

- Quick Compression: The ears can be easily squeezed together to tighten the clamp around the hose, allowing for fast adjustments.

- Flexible Positioning: The clamp can be repositioned along the hose before final tightening, offering flexibility during installation.

- Clear Visibility: The clamp’s position is visible, allowing for easy alignment with the hose and fitting.

- Reusable: Many ear clamps can be reused if undamaged during removal, making them convenient for repairs and adjustments.

These features contribute to the ease of use, making ear hose clamps a popular choice for securing hoses in automotive, plumbing, and industrial applications.

For any doubt & Query write us at: sales3@natronequipments.com

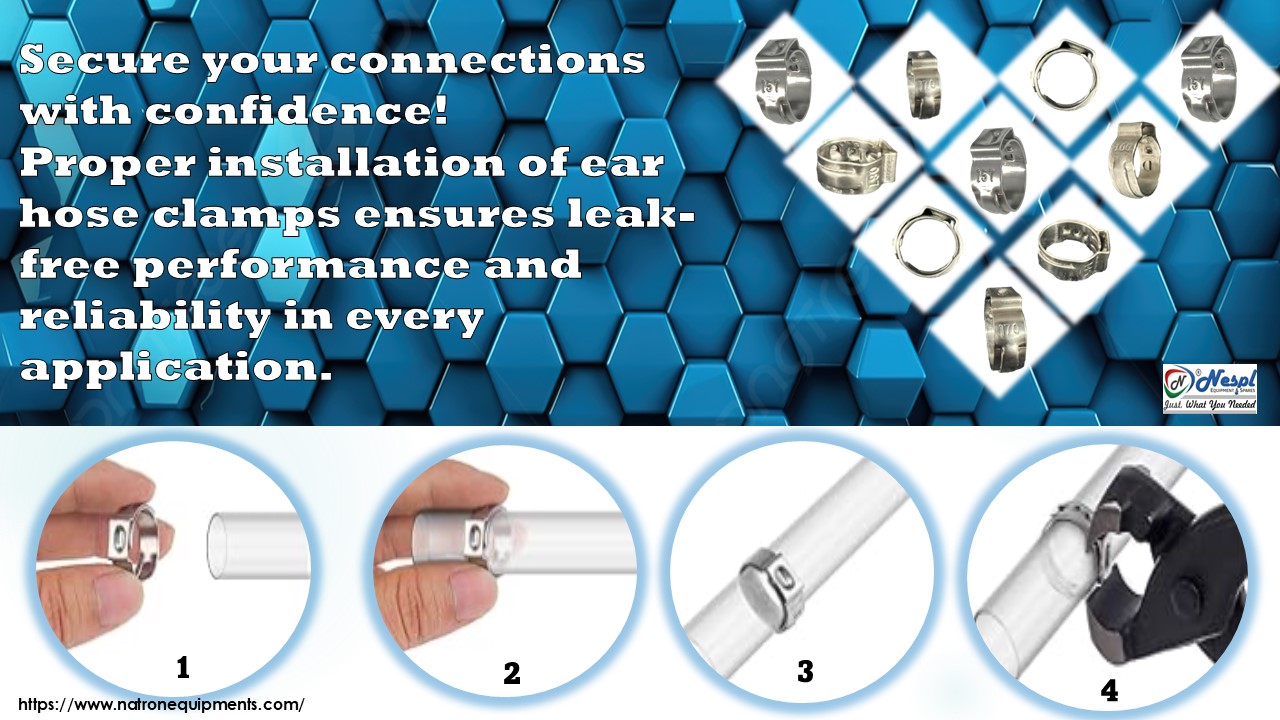

Step-by-Step Guide to Installing Ear Hose Clamps

Installing an ear hose clamp is a straightforward process. Follow these steps for a secure installation:

Tools Needed:

- Ear hose clamp

- Pliers (preferably needle-nose)

- (Optional) Lubricant for the hose

Installation Steps:

- Prepare the Hose and Fitting:

- Ensure the hose is cut to the correct length and is clean.

- If needed, apply a small amount of lubricant to the hose end to make the installation easier.

- Position the Hose:

- Slide the hose onto the fitting or connector, making sure it is pushed all the way in.

- Place the Clamp:

- Slide the ear hose clamp over the hose, positioning it about 1/8 to 1/4 inch from the end of the hose, ensuring it covers the fitting.

- Compress the Clamp:

- Using pliers, grasp the two “ears” of the clamp and squeeze them together to tighten the clamp around the hose.

- Adjust the Clamp:

- While squeezing the ears together, slide the clamp slightly down the hose until it’s securely positioned against the fitting.

- Release the Clamp:

- Once the clamp is in place, carefully release the pliers. The clamp should stay securely fastened around the hose.

- Check the Fit:

- Ensure the hose is snug against the fitting without gaps. The clamp should hold the hose firmly without pinching or damaging it.

- Final Inspection:

- Inspect the installation to make sure everything is secure and properly aligned.

Tips for Easier Installation:

- If the clamp feels loose after installation, you may need to adjust or replace it.

- If the clamp is hard to slide or adjust, applying a bit of lubricant can help ease the process.

Must visit to explore more: https://www.natronequipments.com/various-industry-products/nespl-clamps-and-tools

Conclusion

Installing ear hose clamps is a simple and efficient way to secure hoses in a variety of settings, including automotive, plumbing, and industrial applications. Their ease of installation, strong grip, and reusability make them a popular choice. By following this step-by-step guide and using the proper tools, you can ensure a secure and effective installation.

Must Visit to explore more: https://www.natronequipments.com/