Gear pumps, specifically external and internal gear pumps, play a vital role as positive displacement pumps in various industries. In this blog, we will explore the interesting world of gear pumps. We will explore their features, working principles, and applications, as well as their advantages and disadvantages. By the end, you’ll understand these pumps and their significance in fluid transfer processes.

Gear Pump Features:

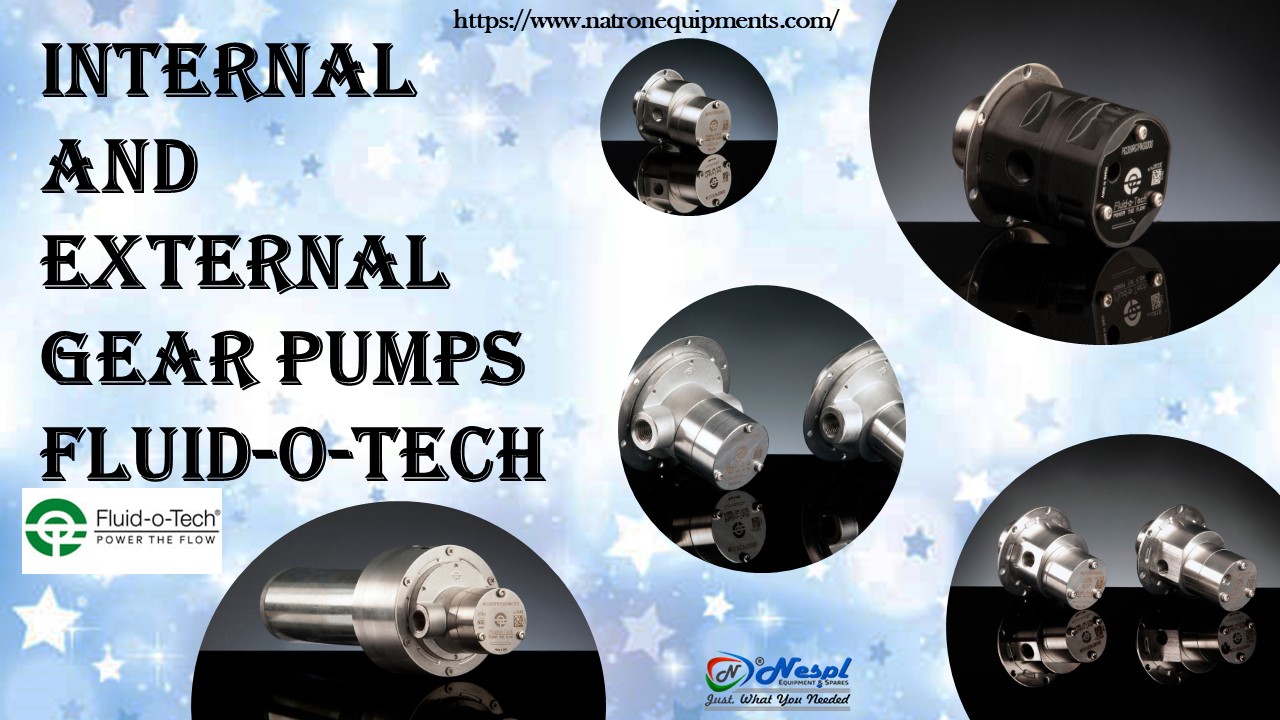

Gear pumps come in two primary models: external and internal. Both models share common characteristics:

- Consist of two identical gears, with one functioning as the driving gear and the other as the idle gear.

- The gears are precisely meshed side by side within a housing.

- Smooth operation is ensured by bearings located on both sides of each gear shaft.

- Efficient transportation of fluid between ports is achieved by trapping it between the gear teeth.

- Leakage is prevented by the gear mesh, which acts as a reliable seal.

Want to explore more Fluid-O-Tech Pumps, must visit:

https://www.natronequipments.com/brand/fluid-o-tech.html

Working Principles of Gear Pumps:

External Gear Pumps:

- In external gear pumps, two gears mesh together within a tightly fitting housing.

- Fluid fills the spaces between the gear teeth, creating a circulation around the gears.

- Due to the meshing of the teeth, the fluid is unable to pass through and is expelled through the outlet.

Internal Gear Pumps:

- Internal gear pumps utilize a system of two meshing gears, with the outer gear (ring gear) driving the inner gear (idler gear).

- Fluid trapped between the gears is transferred from the inlet port to the outlet port.

- The gear mesh acts as a seal, preventing leakage between the ports.

- Some internal gear pumps incorporate a crescent component to enhance internal sealing.

Applications of Gear Pumps:

Gear pumps find widespread applications across various industries due to their versatility and efficiency in fluid transfer processes. Here are some notable application areas:

- Industrial Processes: Gear pumps are widely used in industrial settings for handling fluids such as lubricants, chemicals, and viscous materials.

- Automotive Industry: Gear pumps are utilized in automotive systems for tasks like oil circulation, fuel injection, and hydraulic power steering.

- Oil and Gas: Gear pumps play a crucial role in oil and gas operations, including metering, transfer, and injection of fluids.

- Food and Beverage: Gear pumps are suitable for pumping food-grade liquids, such as syrups, chocolate, and sauces, due to their hygienic design.

- Pharmaceuticals: Gear pumps are employed in pharmaceutical manufacturing for precise metering, transferring liquids, and handling sensitive materials.

Advantages of Gear Pumps:

Gear pumps offer numerous advantages that contribute to their popularity in various industries. Here are the key advantages:

- Smooth Operation: Gear pumps provide minimal pressure pulsations, ensuring a steady and uniform fluid flow.

- Precision and Accuracy: Gear pumps offer high levels of accuracy and precision, making them ideal for applications that require precise fluid metering.

- Bidirectional Functionality: Gear pumps are reversible, allowing them to pump fluids in both directions, enhancing versatility in fluid transfer systems.

- Compatibility with Hazardous and Hygienic Fluids: Gear pumps can handle a wide range of fluids, including hazardous chemicals and hygienic substances, meeting diverse industry requirements.

- Excellent Suction Capability: Gear pumps exhibit excellent suction capability, preventing the formation of air pockets and ensuring efficient fluid transfer.

- Durability and Longevity: Gear pumps are known for their robust construction and long-term performance, making them reliable and durable in demanding industrial environments.

- Reliable Sealing: Gear pumps provide reliable sealing, even in complex applications, reducing the risk of leakage and ensuring efficient fluid transfer.

- Temperature Adaptability: Gear pumps can operate effectively in both high and low-temperature environments, making them suitable for a wide range of applications.

- Versatile Design and Sizing Options: Gear pumps come in various designs and sizes, allowing for customization and integration with different engines and systems.

- Favourable Quality-Price Ratio: Gear pumps offer a competitive quality-price ratio compared to similar pumps available in the market, making them a cost-effective choice for fluid transfer processes.

Disadvantages of Gear Pumps:

Although gear pumps possess significant advantages, it’s crucial to acknowledge their limitations in certain scenarios. Here are the primary disadvantages to consider:

- Unsuitability for Dry Processes: Gear pumps are not suitable for extended periods of dry operation, as it can lead to damage to the gears. It is important to ensure a continuous flow of fluid to prevent potential issues.

- Handling Abrasive Fluids: When dealing with abrasive fluids, gear pumps may require additional bearings and tighter tolerances to withstand the wear caused by the particles. Proper maintenance and monitoring are necessary to avoid premature wear and failure.

- Inability to Handle Suspended Solids: Gear pumps are not designed to pump liquids containing suspended solids. The presence of solid particles can lead to clogging and damage to the pump internals. Alternative pump types may be more suitable for applications involving fluids with suspended solids.

Conclusion

Gear pumps, particularly external and internal gear pumps, play a vital role as positive displacement pumps across various industries. They offer a range of features and advantages that make them a preferred choice for fluid transfer processes. With their precise meshing gears, smooth operation, and reliable sealing, gear pumps ensure efficient and accurate fluid transportation. They find applications in industrial processes, automotive systems, oil and gas operations, food and beverage production, and pharmaceutical manufacturing.

Gear pumps provide advantages such as stable fluid flow, bidirectional functionality, compatibility with hazardous and hygienic fluids, excellent suction capability, durability, and temperature adaptability. Their versatile design and favourable quality-price ratio further enhance their appeal in the market.

However, it’s important to be aware of their limitations. Gear pumps are not suitable for extended dry operation, and handling abrasive fluids may require additional precautions. They are also not designed to handle liquids containing suspended solids.

If you’re considering purchasing gear pump, NESPL is a reliable provider where you can find a wide range of gear pumps to suit your specific needs. With their expertise and quality products, NESPL can assist you in acquiring the right gear pumps for your fluid transfer requirements.

Must Visit: https://www.natronequipments.com/

Choose gear pump and harness their power to optimize your fluid transfer processes with efficiency and precision.

For any doubt directly connect to: sales@natronequipments.com